1904 Cameron Roadster

Inventory Number: 3045

$67,500

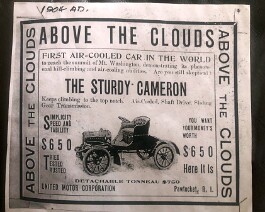

Everett S. Cameron founded the Cameron Automobile Company in 1899 in Massachusetts, producing vehicles from 1903 to 1914 and

sporadically between 1916 and 1920. His first cars were steam-powered, but once funding was acquired, he began producing internal

combustion, air-cooled vehicles and went on to produce trucks, tractors, and even boats in addition to cars. The Cameron set industry

standards with their innovation, including left-side steering wheels, and front-mounted, air-cooled engines.

Cameron employed the James W. Brown Company of Pawtucket, Rhode Island to produce their first single-cylinder vehicles, and, in 1904, added two, three, and finally four-cylinder cars to the selection. The Cameron automobiles began garnering attention, even setting world records. In 1906, the Cameron Company relocated back to Massachusetts, opened a plant, and began establishing branch locations, introducing a revolutionary rear-mounted gearbox. They continued expanding until World War I cost them their financial backing, but experienced several rebirths, eventually producing tractors.

The restoration of this car has been fully completed.

FROM THE DICK SHAPPY ARCHIVES:

The Horseless Age (Magazine), Vol. 13, No. 19., 1904

“New Vehicles and Parts: The Cameron Gasoline Runabout.”

By Albert L. Clough

“James Brown Mch. Co., Providence, RI, have brought out a light runabout with a six horse power air-cooled engine, known as the Cameron Car, of which the following is a technical description:-

The frame consists of oak sills and front and rear cross bars strongly framed together. Steel castings form the front spring hangers, and they are securely bolted to the sills. The front springs are 34 inches in length, 1.25 inch wide and composed of four leaves. They are semi- elliptic and shackled at the rear ends. For the rear springs, the double elliptic type is used. They measure 34 inches in length, 1.25 inch in width and consist of four leaves when a tonneau is supplied and of three leaves when the machine is used as a runabout. The front axle consists of a single steel casting of vertical I section, slightly dropped at its central portion and comprising, as integral portions, the steering yokes and the spring plates. Drop forgings are used for the steering pivots and cranks. Twenty-eight-inch artillery wheels are employed, equipped with 2.5 inch detachable tires. The front wheel bearings contain a race of 0.5-inch balls on the inside and ⅜ inch balls on the outside, with suitable adjustments and bronze dust caps.

The tube which forms the rear axle casings is 2 inches in external diameter and of No. 11 gauge steel tubing. The inside ends of its halves are brazed and pinned into the halves of the differential and bevel gear case, which are steel castings and perfectly oil-tight. The halves of the casing are very securely bolted together. A 1-inch shaft of cold rolled steel forms the rear axle and runs on four Hyatt roller bearings, two under the springs and two close to the differential case. These bearings are lubricated by the outflow of oil from the case itself. A bevel differential of two pinions and of such construction that it cannot come apart in service is employed. The main driving gear is of Parson’s manganese bronze, with 44 teeth, and its driving pinion is of machine steel of 12 teeth. In order to overcome the thrust of the rear axle, two ball bearings are used. The bevel gear case is provided with a neck into which is clamped, by means of four steel bolts, a steel tube of two inches outside diameter and No. 11 gauge, which encloses the shaft drive. This tube is provided at its forward end with a yoke which hinges in a bracket on the rear of the change-speed gear case and thus allows up and down motion of the rear axle with respect to the body. Furthermore, the shaft encasing tube may rotate in its front yoke so as to allow for unequal depression of the two sides of the body. Thus complete flexibility is secured. A universal joint connects the driving shaft with the shaft from the speed-change gear and is co-axial with the swiveling yoke of the encasing tube, and thus the necessity of a slip join is obviated, as the length of the driving shaft is held unchangeable by its encasing tube, a slight deformation of the rear springs taking place when the body moves up and down. The springs are so placed that the swiveling pin of the shaft encasing tube is nearly in the same straight line with the two ends of the rear springs and very little backward and forward deformation of the springs is ever demanded. The shaft casing takes all the stresses off the driving shaft and acts effectually as a distance rod.

Integral with the hubs of the rear wheels are malleable iron brake drums, and brazed and pinned to the ends of the rear axle casings are the expanding members which act as brake shoes. These are two semi-circular steel drums hinged together at one end and capable of being expanded by a cam acting between their free ends. They are leather faced and act effectively in either direction of the vehicle’s motion. These brakes are operated by means of a pedal which moves over a ratchet sector, the first motion of which releases the clutch. A coasting position is provided between the point of clutch release and that at which the brakes begin to set. Steering is by means of a large wood wheel with brass spider, the shaft of which passes through the column and terminates in a crank with a ball joint that acts directly, through a rod, to the steering mechanism, which is suppled throughout with adjustable ball joints.

The motive power of the car is six horse power, single cylinder, vertical engine mounted in front under a stamped steel bonnet of the square type and provided with gauze front and two doors in its top. The motor consists of four portions, viz., the lower half of the crank case; the upper part of the crank case, upon which are cast two wide feet by which the mechanism is fastened to the frame by means of bolts; the cylinder proper, which is covered with deep, horizontal, annular cooling ribs, and the head, which is also deeply corrugated for cooling purposes and packed to the cylinder proper by means of a copper gasket. The lower and upper crank case halves are securely bolted together and the cylinder head and cylinder are secured to the upper crank case half by means of four long steel through bolts. The cylinder bore is accurately reamed to a diameter of 4 ⅛ inches, and the engine stroke is 4 inches. Both valves are located directly in the head, side by side, and are covered by housings which are removable after taking out two bolts. The spark plug enters the combustion chamber between the valves and slightly behind them. The exhaust valve has a diameter of 2 inches and a lift of ⅜ inch. It is constructed with a nickel steel stem screwed and riveted into a cast iron head with a 45 degree seat. The inlet valve is of 1 ¾ inch diameter and is made from a drop forging of soft machine steel. Deep flanges are provided on the exhaust valve housing and the pipe leading from it and it is so placed as to receive the full blast of cooling air. A drop forged steel crankshaft is employed, which is 2 ⅜ inches in diameter at all bearings. The main bearing under the flywheel is 3 ½ inches long, the front one 2 ½ inches long, and that at the pin 2 inches long. The counterweight, which preserves the balance of the shaft, is cast onto two pins which are inserted into the shaft and the metal poured into a mould which is formed about them. It is thus impossible for the counterweight to work loose. The main bearing bushings are of phosphor bronze, the same metal being employed for the connecting rod, which has a pyramidal I section. Its bearings on the crankshaft is adjustable. The wrist pin is hollow and of ¾ inch diameter. Three obliquely cut packing rings are employed on the piston. The flywheel is of 13 ½ inches outside diameter, weighs 75 pounds and is coned out to form the female member of the clutch. The cam case is cast in the upper crank case section and is closed by a bronze plate that carries a boss upon which may rotate the igniter case.

A single steel casting forms the large gear of the secondary pair, the exhaust cam, the spark cam and the secondary shaft renders their slipping impossible. The exhaust valve push rod passes upward through a boss in the case cam and actuates a rocker arm which acts directly upon the stem of the exhaust valve. The exhaust valve spring consists of a loop of flat spring steel having hole in its ends which are passed over the exhaust valve stem and secured in position by a split pin. A spring of this form is found not to be affected by heat, as is a spiral spring. The valve push rod has a roller follower and its connection to the exhaust rocker arm is through a spiral spring which somewhat cushions its action and obviates much noise. A bronze box forms the spark timer case and the contact mechanism consists of a steel spring or trembler which bears upon the cam and is forced into contact with a platinum tipped screw which enters the box through a vulcanite bushing. The spring is very easily replaced in case of breaking.

The fan shaft screws into a boss on the cylinder castings and carries a ball-bearing pulley and an 11-inch four-blade propeller fan which delivers its air directly upon the combustion space and valve housings. Upon the crank shaft, is located the fan driving pulley which is integral with the starting ratchet - teeth being cast on the pulley hub face for engagement with the permanently attached, spring released starting crank.

Splash lubrication is relied upon for all portions of the engine, a supply of lubricant being at all times carried in the bottom of the crank case. All bearings have oil ways, and the wrist pin is hollow and grooved to receive its lubrication from the cylinder walls. All internal parts of the crank and gear case are coated with a fireproof and oil-proof paint to prevent any metal particles which may be left when the parts are machined from getting into the oil. Oil is supplied to the crank case by means of a plunger pump that draws the lubricant from a tank located on the outside of the dash under the hood, and forces it into the bottom of the engine base. This pump is operated by the foot and its plunger is spring returned. About every fifteen miles, which the machine is in operation, one pump full of oil should be injected into the base. The oil tank has a capacity of one gallon and is so placed that it is always warm enough to ensure the requisite fluidity of the lubricant.

The exhaust pipe extends from the engine in a smooth curve, in order to avoid friction of the gases, and enters the inside compartment of the muffler through one-quarter inch holes, passes into the outside compartment through a large number of perforations, and enters a multiplicity of small holes in a ⅜ inch pipe in the outer muffler compartment, from which it escapes to the air. Ignition is by means of a non-vibrating coil supplied from four cells of dry battery sealed with paraffine into a box; the coil and battery being carried under the right hand side of the seat.

At 1,200 revolutions per minute the engine is stated to develop six horse power and to give the car a speed of eighteen miles per hour on the high gear.

A carburetor of the float feed spraying type is employed and is mounted upon the engine foot. When the inlet valve is removed the carburetor pipe lifts out of its couplings. The throttle, as well as the spark timing lever, is carried upon the steering head on the ratchet sector and the throttle, when thrown to its extreme starting position, is so arranged as to cut off the carburetor air supply entirely, while leaving the gasoline supply open. The result is, that when the engine is cranked preliminary to throwing in the switch, the carburetor is automatically flooded and, when the throttle is thrown to an intermediate position, a rich mixture will pass to the engine.

The change-speed gear is of the sliding type and gives two forward speeds and a reverse. The ratio of engine turns to rear wheel turns is five to one on the high speed and fifteen to one on the low gear. The gear case is oil tight, and sepeerates centrally in a vertical plane, each half of the case being bolted to the frame by two feet. The gears are cut from solid steel and case hardened, and are carried on 1 ⅛ inch shafts, running in phosphor bronze bushings 2 ¼ inches long. The gears are of eight pitch and of ¾ inch face. At the forward end of the gear case, is a ball thrust bearing designed to counteract end pressure from the leather lined cone clutch, which engages in the flywheel by means of the usual spiral spring, and which is thrown out, as previously described, by means of the pedal. The gears are shifted by means of a lever on the steering column which operates over a four notched segment and affords a neutral position as well as the three speeds.

Without the tonneau, the machine weights 700 pounds, and when carrying the tonneau, its weight is 800 pounds. When the tonneau is detached a sloping board takes its place, and the very large amount of space beneath this may be used for tools or supplies, as may a portion of the room under the front seat. The gasoline tank is attached to the upper portion of the seat frame, and is very large and shallow, its capacity being 6 ½ gallons. The car body is permanently attached to the sills, but the removal of the floor renders all portions of the mechanism perfectly accessible. Fourteen coats of paint and varnish are supplied to the body to secure the final finishes, and genuine hair and leather are used in the upholster. Laminated wood mud guards and bronze lamp supports are provided. The wheel base is 76 inches and the read either 54 inches or 46 inches as desired.”

Note: Some of the typos in the original article have been edited for clarity.

Cameron employed the James W. Brown Company of Pawtucket, Rhode Island to produce their first single-cylinder vehicles, and, in 1904, added two, three, and finally four-cylinder cars to the selection. The Cameron automobiles began garnering attention, even setting world records. In 1906, the Cameron Company relocated back to Massachusetts, opened a plant, and began establishing branch locations, introducing a revolutionary rear-mounted gearbox. They continued expanding until World War I cost them their financial backing, but experienced several rebirths, eventually producing tractors.

The restoration of this car has been fully completed.

- ENGINE: Single-cylinder, air-cooled

- VIN: 7

- HP: 6

- WHEELBASE: 76 in.

- WHEELS: Artillery

- MANUFACTURED: Pawtucket, Rhode Island

- WEIGHT: 700-750 LB

- FEATURES & RESTORATIONS:

- Diamond-tufted seats

- Engine inspection door

- Straightened ventilation louvers

- New red linoleum flooring with mitered corner brass molding

- Gray foot panels, gas tank, fenders, and fender brackets with proper period-correct "carriage bolts"

- Restored steering wheel, steering column, brake and clutch pedals and related linkages, transmission, and drive train

- Spark advance and gas throttle rods and indicators have been added to the steering column

- Original body tag for Cameron Car made by James Brown Machine Company in Pawtucket, Rhode Island.

- Period-correct (neverout) license plate bracket fitted to period-correct triple tier lantern bracket and period-correct lantern

- An early brass electric klaxon horn was located, restored, and placed on the dashboard.

FROM THE DICK SHAPPY ARCHIVES:

The Horseless Age (Magazine), Vol. 13, No. 19., 1904

“New Vehicles and Parts: The Cameron Gasoline Runabout.”

By Albert L. Clough

“James Brown Mch. Co., Providence, RI, have brought out a light runabout with a six horse power air-cooled engine, known as the Cameron Car, of which the following is a technical description:-

The frame consists of oak sills and front and rear cross bars strongly framed together. Steel castings form the front spring hangers, and they are securely bolted to the sills. The front springs are 34 inches in length, 1.25 inch wide and composed of four leaves. They are semi- elliptic and shackled at the rear ends. For the rear springs, the double elliptic type is used. They measure 34 inches in length, 1.25 inch in width and consist of four leaves when a tonneau is supplied and of three leaves when the machine is used as a runabout. The front axle consists of a single steel casting of vertical I section, slightly dropped at its central portion and comprising, as integral portions, the steering yokes and the spring plates. Drop forgings are used for the steering pivots and cranks. Twenty-eight-inch artillery wheels are employed, equipped with 2.5 inch detachable tires. The front wheel bearings contain a race of 0.5-inch balls on the inside and ⅜ inch balls on the outside, with suitable adjustments and bronze dust caps.

The tube which forms the rear axle casings is 2 inches in external diameter and of No. 11 gauge steel tubing. The inside ends of its halves are brazed and pinned into the halves of the differential and bevel gear case, which are steel castings and perfectly oil-tight. The halves of the casing are very securely bolted together. A 1-inch shaft of cold rolled steel forms the rear axle and runs on four Hyatt roller bearings, two under the springs and two close to the differential case. These bearings are lubricated by the outflow of oil from the case itself. A bevel differential of two pinions and of such construction that it cannot come apart in service is employed. The main driving gear is of Parson’s manganese bronze, with 44 teeth, and its driving pinion is of machine steel of 12 teeth. In order to overcome the thrust of the rear axle, two ball bearings are used. The bevel gear case is provided with a neck into which is clamped, by means of four steel bolts, a steel tube of two inches outside diameter and No. 11 gauge, which encloses the shaft drive. This tube is provided at its forward end with a yoke which hinges in a bracket on the rear of the change-speed gear case and thus allows up and down motion of the rear axle with respect to the body. Furthermore, the shaft encasing tube may rotate in its front yoke so as to allow for unequal depression of the two sides of the body. Thus complete flexibility is secured. A universal joint connects the driving shaft with the shaft from the speed-change gear and is co-axial with the swiveling yoke of the encasing tube, and thus the necessity of a slip join is obviated, as the length of the driving shaft is held unchangeable by its encasing tube, a slight deformation of the rear springs taking place when the body moves up and down. The springs are so placed that the swiveling pin of the shaft encasing tube is nearly in the same straight line with the two ends of the rear springs and very little backward and forward deformation of the springs is ever demanded. The shaft casing takes all the stresses off the driving shaft and acts effectually as a distance rod.

Integral with the hubs of the rear wheels are malleable iron brake drums, and brazed and pinned to the ends of the rear axle casings are the expanding members which act as brake shoes. These are two semi-circular steel drums hinged together at one end and capable of being expanded by a cam acting between their free ends. They are leather faced and act effectively in either direction of the vehicle’s motion. These brakes are operated by means of a pedal which moves over a ratchet sector, the first motion of which releases the clutch. A coasting position is provided between the point of clutch release and that at which the brakes begin to set. Steering is by means of a large wood wheel with brass spider, the shaft of which passes through the column and terminates in a crank with a ball joint that acts directly, through a rod, to the steering mechanism, which is suppled throughout with adjustable ball joints.

The motive power of the car is six horse power, single cylinder, vertical engine mounted in front under a stamped steel bonnet of the square type and provided with gauze front and two doors in its top. The motor consists of four portions, viz., the lower half of the crank case; the upper part of the crank case, upon which are cast two wide feet by which the mechanism is fastened to the frame by means of bolts; the cylinder proper, which is covered with deep, horizontal, annular cooling ribs, and the head, which is also deeply corrugated for cooling purposes and packed to the cylinder proper by means of a copper gasket. The lower and upper crank case halves are securely bolted together and the cylinder head and cylinder are secured to the upper crank case half by means of four long steel through bolts. The cylinder bore is accurately reamed to a diameter of 4 ⅛ inches, and the engine stroke is 4 inches. Both valves are located directly in the head, side by side, and are covered by housings which are removable after taking out two bolts. The spark plug enters the combustion chamber between the valves and slightly behind them. The exhaust valve has a diameter of 2 inches and a lift of ⅜ inch. It is constructed with a nickel steel stem screwed and riveted into a cast iron head with a 45 degree seat. The inlet valve is of 1 ¾ inch diameter and is made from a drop forging of soft machine steel. Deep flanges are provided on the exhaust valve housing and the pipe leading from it and it is so placed as to receive the full blast of cooling air. A drop forged steel crankshaft is employed, which is 2 ⅜ inches in diameter at all bearings. The main bearing under the flywheel is 3 ½ inches long, the front one 2 ½ inches long, and that at the pin 2 inches long. The counterweight, which preserves the balance of the shaft, is cast onto two pins which are inserted into the shaft and the metal poured into a mould which is formed about them. It is thus impossible for the counterweight to work loose. The main bearing bushings are of phosphor bronze, the same metal being employed for the connecting rod, which has a pyramidal I section. Its bearings on the crankshaft is adjustable. The wrist pin is hollow and of ¾ inch diameter. Three obliquely cut packing rings are employed on the piston. The flywheel is of 13 ½ inches outside diameter, weighs 75 pounds and is coned out to form the female member of the clutch. The cam case is cast in the upper crank case section and is closed by a bronze plate that carries a boss upon which may rotate the igniter case.

A single steel casting forms the large gear of the secondary pair, the exhaust cam, the spark cam and the secondary shaft renders their slipping impossible. The exhaust valve push rod passes upward through a boss in the case cam and actuates a rocker arm which acts directly upon the stem of the exhaust valve. The exhaust valve spring consists of a loop of flat spring steel having hole in its ends which are passed over the exhaust valve stem and secured in position by a split pin. A spring of this form is found not to be affected by heat, as is a spiral spring. The valve push rod has a roller follower and its connection to the exhaust rocker arm is through a spiral spring which somewhat cushions its action and obviates much noise. A bronze box forms the spark timer case and the contact mechanism consists of a steel spring or trembler which bears upon the cam and is forced into contact with a platinum tipped screw which enters the box through a vulcanite bushing. The spring is very easily replaced in case of breaking.

The fan shaft screws into a boss on the cylinder castings and carries a ball-bearing pulley and an 11-inch four-blade propeller fan which delivers its air directly upon the combustion space and valve housings. Upon the crank shaft, is located the fan driving pulley which is integral with the starting ratchet - teeth being cast on the pulley hub face for engagement with the permanently attached, spring released starting crank.

Splash lubrication is relied upon for all portions of the engine, a supply of lubricant being at all times carried in the bottom of the crank case. All bearings have oil ways, and the wrist pin is hollow and grooved to receive its lubrication from the cylinder walls. All internal parts of the crank and gear case are coated with a fireproof and oil-proof paint to prevent any metal particles which may be left when the parts are machined from getting into the oil. Oil is supplied to the crank case by means of a plunger pump that draws the lubricant from a tank located on the outside of the dash under the hood, and forces it into the bottom of the engine base. This pump is operated by the foot and its plunger is spring returned. About every fifteen miles, which the machine is in operation, one pump full of oil should be injected into the base. The oil tank has a capacity of one gallon and is so placed that it is always warm enough to ensure the requisite fluidity of the lubricant.

The exhaust pipe extends from the engine in a smooth curve, in order to avoid friction of the gases, and enters the inside compartment of the muffler through one-quarter inch holes, passes into the outside compartment through a large number of perforations, and enters a multiplicity of small holes in a ⅜ inch pipe in the outer muffler compartment, from which it escapes to the air. Ignition is by means of a non-vibrating coil supplied from four cells of dry battery sealed with paraffine into a box; the coil and battery being carried under the right hand side of the seat.

At 1,200 revolutions per minute the engine is stated to develop six horse power and to give the car a speed of eighteen miles per hour on the high gear.

A carburetor of the float feed spraying type is employed and is mounted upon the engine foot. When the inlet valve is removed the carburetor pipe lifts out of its couplings. The throttle, as well as the spark timing lever, is carried upon the steering head on the ratchet sector and the throttle, when thrown to its extreme starting position, is so arranged as to cut off the carburetor air supply entirely, while leaving the gasoline supply open. The result is, that when the engine is cranked preliminary to throwing in the switch, the carburetor is automatically flooded and, when the throttle is thrown to an intermediate position, a rich mixture will pass to the engine.

The change-speed gear is of the sliding type and gives two forward speeds and a reverse. The ratio of engine turns to rear wheel turns is five to one on the high speed and fifteen to one on the low gear. The gear case is oil tight, and sepeerates centrally in a vertical plane, each half of the case being bolted to the frame by two feet. The gears are cut from solid steel and case hardened, and are carried on 1 ⅛ inch shafts, running in phosphor bronze bushings 2 ¼ inches long. The gears are of eight pitch and of ¾ inch face. At the forward end of the gear case, is a ball thrust bearing designed to counteract end pressure from the leather lined cone clutch, which engages in the flywheel by means of the usual spiral spring, and which is thrown out, as previously described, by means of the pedal. The gears are shifted by means of a lever on the steering column which operates over a four notched segment and affords a neutral position as well as the three speeds.

Without the tonneau, the machine weights 700 pounds, and when carrying the tonneau, its weight is 800 pounds. When the tonneau is detached a sloping board takes its place, and the very large amount of space beneath this may be used for tools or supplies, as may a portion of the room under the front seat. The gasoline tank is attached to the upper portion of the seat frame, and is very large and shallow, its capacity being 6 ½ gallons. The car body is permanently attached to the sills, but the removal of the floor renders all portions of the mechanism perfectly accessible. Fourteen coats of paint and varnish are supplied to the body to secure the final finishes, and genuine hair and leather are used in the upholster. Laminated wood mud guards and bronze lamp supports are provided. The wheel base is 76 inches and the read either 54 inches or 46 inches as desired.”

Note: Some of the typos in the original article have been edited for clarity.